The rules of tennis specify that only approved tennis balls can be used in major tournaments. An approved ball must have a certain weight (about 57 grams), diameter (about 65 mm) and colour (white or yellow). It must also have a certain stiffness and it must bounce to the right height (between 53 and 58 inches) when dropped from a height of 100 inches onto a rigid surface such as a concrete slab. In addition, it must have an approved value of the return deformation. This last quantity appears to have no obvious or direct relevance to the performance of a tennis ball, but it has been written into the rules of tennis since the 1960s. To see why, it is necessary to delve into the history of tennis balls.

I have a rule book of 1955 from when I first became seriously interested in tennis, and there is no mention of the return deformation. There is mention of the deformation, now called the forward deformation, since that determines the stiffness of the ball. Players use a similar test when they squeeze a ball to feel how stiff or soft it is. The official test in 1955 was to squeeze the ball with a force of 18 lb, in which case an approved ball had to squash by more than 0.265 inch (6.73 mm) and less than 0.290 inch (7.37 mm) across any diameter. Modern balls are allowed to be slightly stiffer since the limits are now 5.6 mm to 7.4 mm, at least for the most common type of ball, known as a Type 2 ball. The ITF also approves an even stiffer ball, known as a Type 1 ball, where the forward deformation limits are 5.0 to 6.0 mm. The Type 1 ball is popular on European clay courts.

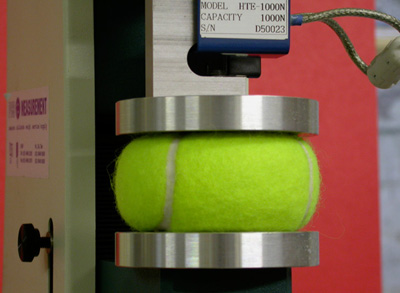

The return deformation is a quantity that measures whether the ball remains squashed after it has been squashed or how quickly it returns to its original shape (Fig. 1). A ball made from plasticene will not return to its original shape after it is squashed. A metal spring does return to its original shape after it has been compressed or stretched and it does so very rapidly. The behaviour of a tennis ball, like most other sports balls, is between that of a metal spring and a plasticene ball.

Figure 1 — Stiffness/deformation test.

A tennis ball remains slightly deformed after it is squashed, especially if it is squashed for a long period of time and if it is squashed by a large amount. It is hard to measure by eye, but if you stand on a ball and then take a close look, the ball will be slightly egg-shaped. The same effect occurs when a ball is struck with a racquet, but to a smaller extent since the ball remains squashed for only a very short time while it is on the strings. Nevertheless, the ball takes time to recover its shape and it doesn't completely recover by the time it bounces off the strings or off the court. That is part of the reason why a ball does not bounce to a height of 100 inches when dropped from a height of 100 inches. It bounces to a height of only 53 to 58 inches. The ball squashes by about 6 mm during the bounce, but if it expands by only 4 mm during the last half of the bounce then it won't bounce back up to the original drop height. The ball recovers its shape quickly after it bounces, but that is too late to allow the ball to bounce back to its original drop height. During the bounce, some of the original energy gained by the falling ball is lost in the ball as it squashes and then expands.

The return deformation test was introduced by the International Tennis Federation when pressureless balls started to appear on the market in the late 1950s. Before that time, tennis balls were made as hollow rubber balls with a cloth cover and contained compressed air inside to increase their stiffness. The compressed air allowed the ball to return to its original shape more quickly, so the ball bounced higher, and it prevented the rubber from deforming too much and becoming permanently deformed. The compressed air gradually leaks out so manufacturers started supplying balls in metal cans after about 1940, and that is how they are still being supplied today. If air in the can is at the same pressure as the air inside the ball then the air inside can't leak out. Once the can is opened, air starts leaking out of the ball and the ball becomes softer after a few sets or after a few weeks just sitting on a shelf without being used. The cloth on the ball also wears thin or fluffs up during play, so players stop using them when the cloth is worn or when the ball is too soft.

The idea behind the invention of the pressureless ball was to avoid the air leak problem by making a rubber tennis ball with air at atmospheric pressure inside the ball. Since there was no excess air pressure inside the ball, the stiffness of the ball had to be increased by using a stiffer type of rubber and by increasing the thickness of the rubber wall while still keeping the overall weight of the ball the same. The technical difficulties of manufacturing a suitable ball are outlined in some early patents, including US Patents 2,896,949 (Dunker, 1959), 3,428,314 (Haines et al, 1969), 4,022,469 (Lacoste et al, 1977), 4,306,719 (Haines et al. 1981) and 5,225,258 (Nakamura et al. 1993) which can be found on Google patents.

Problems with early versions of these pressureless balls were that they were too soft or too hard or they became too soft after only one or two sets due to permanent deformation of the rubber. It was in response to these problems that the ITF introduced the return deformation test.

Part of the new test involved squashing the ball by one inch and then measuring the change in diameter of the ball when the force was reduced back to 18 lb. That became a significant pass or fail test of pressureless balls since it tested the ability of the rubber to regain its shape without the assistance of any compressed air inside the ball (other than by compression of the atmospheric pressure air already inside the ball). And it was a tougher test than the bounce height test since a ball squashes by only about 1/4 inch when it is dropped from a height of 100 inches and it squashes for only 0.005 seconds. The return deformation test measures the ability of a ball to recover after significant deformation and therefore measures whether the ball is likely to retain its original properties after several sets of play.

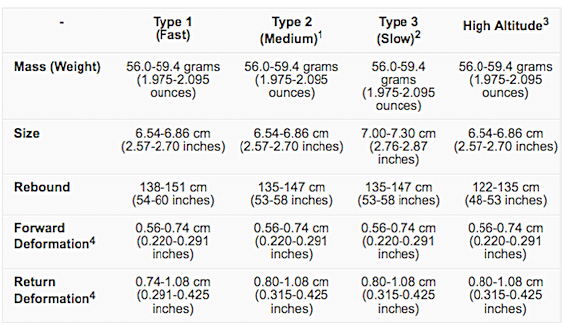

Regardless of whether a ball contains air at high pressure or not, all tennis balls tend to become softer with use. In the case of pressurised balls, it is because air inside the ball leaks out. In the case of pressureless balls, it is because rubber loses its original stiffness as a result of permanent deformation after many compression cycles. Manufacturers responded by making balls slightly stiffer than allowed so that balls would retain the correct stiffness over a longer period of time before becoming too soft. European players in particular liked the feel of the stiffer balls, with the result that the ITF decided to make them legal by introducing new regulations regarding ball stiffness. At present, four different types of ball are approved for tournament play, as indicated in Fig. 2. The most popular type is the Type 2 ball. See also the official ITF rules at https://www.itftennis.com/technical/publications/rules/balls/appendix-i.aspx

Figure 2 — The four ball types allowed by the 2018 rules of tennis. All have the same weight.